Rousselet Robatel monostage centrifugal extractors have been used widely in industries such as the pharmaceutical, fine chemical, food products, nuclear…..

|

|

|

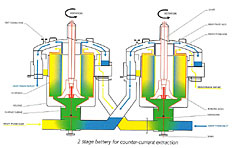

| 9 stage centrifugal extractor battery – Model BXP 360 | Two stage battery Model BXP 360 Kynar construction | Process flow diagram of two stage BXP centrifugal extractor |

These monostage centrifugal extractors, also known as centrifugal contactors, annular centrifugal contactors, or liquid / liquid extraction centrifuges offer the following advantages and benefits:

- Counter-current continuous extraction for maximum efficiency

- Direct motor coupling to the main shaft

- Short retention time and low liquid holdup

- Well adapted to batch or continuous operation

- Optional CIP [Clean in place] systems

- cGMP designs for multi-product pharmaceutical processing

- No Bottom Bearing in process area

- Centrifugal force provides efficient phase separation

- Unique Kynar [PVDF] construction for corrosive applications

- Low mix designs for shear sensitive systems

- Unattended operation

- High throughputs achieved in compact machine

- High extraction efficiency typically greater than 95% theoretical

- Connected in series to achieve required number of stages

- No interstage pumps required

- Rapid operational equilibrium

- Laboratory, pilot, and industrial scale machines available

- Cart or skid mounted systems for easy portability

- Rental equipment available

- Internal recycling systems

- Forward extraction, back extraction, scrubbing, water-washing, closed loop extraction, fractional extraction

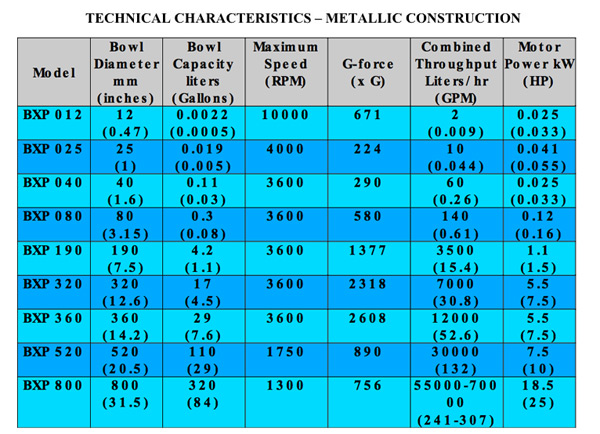

Click image for large view of table

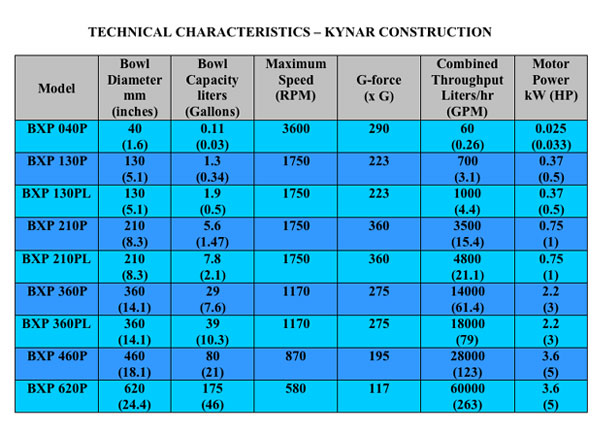

Click image for large view of table

- General Brochure (pdf)

- Monostage centrifugal extractor brochure (pdf)

- Monostage centrifugal extractor operating principle (pdf)

TYPES OF APPLICATIONS

- Pharmaceutical (pdf)

- Agricultural Food Products (pdf)

- Hydrometallurgy (pdf)