ROUSSELET ROBATEL designs and fabricates Continuous Horizontal Screening Centrifuges, to separate, wash, and de-water solid / liquid slurries on a continuous basis. Robust and reliable, the Model EC horizontal continuous centrifuge is ideal for large scale mono-product processing in the chemical and food industries.

|

|

|

| Model EC03 semi-works scale horizontal continuous centrifuge |

Model EC06 screening centrifuge for large scale production |

Horizontal screening centrifuge with casing open |

ADVANTAGES AND CHARACTERISTICS

Performance:

- Suitable for many applications, with high G-forces of 2000-2500 x G, and can operate at process temperatures ranging 0-200°C [32-390°F], adapted for rigid crystals down to 50 microns.

- High production throughputs

- Easy solids discharge, particularly for sticky products, a vibrator can be installed on the discharge screw.

- Torque limitor to prevent overloading of the gear reducer.

Robust:

- Perfectly adapted to continuous processes and robust construction for long-term use.

- Vibration isolators installed on the frame, specifically designed for heavy equipment use.

- Materials of construction : carbon steel, stainless steel

EASY CLEANING – fully opening casing with easy access for cleaning and maintenance

Click image for larger view image

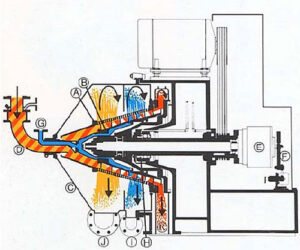

A – Conical basket operating at high rotational speed, with metallic filter screen adapted to the material to be de-watered.

B – Screw conveyor which operates at a differential speed with respect to the basket

C – Outer casing for de-watered product recovery, mother liquor recovery, and wash liquor recovery.

D – Feed tube

E – Gear reducer that controls the differential speed between the basket and screw conveyor

F – Safety mechanism which prevents overloading of the rotating gears.

G – Wash tube

H – Seal that allows the centrifuge to be pressurized for explosion-proof service.

I – Wash liquid outlet

J – Filtrate outlet

K – Dried solids outlet

Operating Principle:

- The slurry to be treated is introduced to the centrifuge through a feed tube (D). Under centrifugal force, the particles are projected against inner surface of the rotating basket.

- The solids are then discharged continuously via a screw conveyor (B), through the outlet opening (K). The liquid fitrate is continuously discharge through the opening (J).

- The wash tube (G) allows wash liquid to be introduced on the surface of the treated product during centrifugation, and before discharging from the back wall.

ROUSSELET ROBATEL can meet the production requirements and knows how to address specific problems, with special machine designs and by providing ancillary equipment upon request.

Downloads: