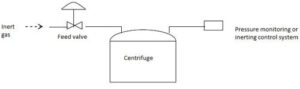

For liquid / liquid extraction or separation and solid / liquid separation applications where processing with flammable solvents is involved, in the chemical and pharmaceutical industries, ROUSSELET ROBATEL has developed inerting systems using pressure monitoring, which are easy to use and reliable, with multipurpose use.

|

|

| Oxygen monitoring system / ICS | Pressure monitoring system |

|

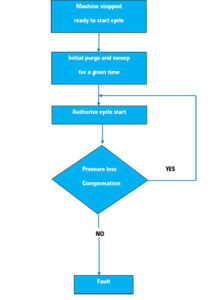

| Inerting process flow diagram |

- SIMPLICITY: Inerting control and purge is maintained using a slight over-pressurization of the vessel, 8-12 mbar.

- RELIABILITY: 0-60 mbar pressure transmitter, with Atex EEx rating for Europe, and to NEC explosion-proof standards for North America, or per local electrical codes.

- SAFETY: Integration of several monitoring devices, allowing for detection of any abnormalities in the inerting system or the installation. This guarantees that the system is properly inerted

- ECONOMICAL: Minimal inert gas consumption, no maintenance is necessary, no sensor replacement.

- MULTI-PURPOSE: Can be used for many applications, depending the volume to be inerted (please contact us)

Operating Principle:

The necessary purge time, flow rate, and pressure to obtain the oxygen level for a safe operation are determined using an oxygen analyzer.

Once the purge time is established, a simple pressure control device at the enclosure will allow for detection of any evidence of abnormal operation in the inerting level without using an oxygen analyzer.

|

| Figure 1 : Typical purging logic diagram |