ROUSSELET ROBATEL designs and fabricates a wide range of centrifuges for hydro- extraction of chips, part de-oiling, and hydro-extraction / drying of parts after surface treatment.

|

||

| Complete turn-key machine-tooling process line | ||

|

|

|

| Special basket for metal cases |

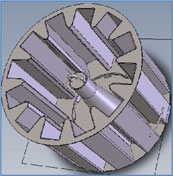

Large scale chip-spinner SC 100 Vx KFO |

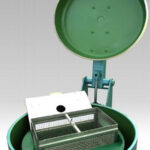

Centrifuge with removable basket TA 60 KC |

These centrifuges, also known as chip wringers, swarf spinners, or parts spinners, are used extensively in the machine-tooling industry.

Advantages and Characteristics

A COMPLETE RANGE – frmo 300 to 1500 mm basket diameters, with useful volumes of 8 liters to 410 liters (total volumes from 15 to 900 liters)

A WIDE RANGE FOR CUSTOM SOLUTIONS ADAPTED TO :

Specific environments and uses:

- Various materials of construction (mild steel, stainless steel, and others) and special coatings

- Option for explosion-proof equipment

The required service and the nature of the products to be treated:

- Baskets with special perforations or filter media (filter bags, screens, etc. )

- Special Baskets : partitioned, with carriers, cases, sectioned, flat or perforated bottom

- Hot air circulation, integrated on the cover or independent system

|

|

|

| Special carrier for metal cases | Basket Model KFO : Discharge through opening bottom | Basket Model KFE : discharge by retractable central cone |

Proven and Optimized Performance

- Automation : Baskets can be removed with a robotic arm (gripping device, transfer, re-installation)

- Several accessories, cycle timers, and easy product discharge

- Possibility for reverse direction of rotation and conical basket to allow parts to tumble to improve drying.

|

|

|

| Robotic gripping arm | Conveyor | Discharging station |

As a worldwide specialist in basket centrifugation, ROUSSELET ROBATEL adapts to your production needs and knows how to respond to specific problems, with special machines and ancillary equipment upon request.

Downloads: