CONTINUOUS BASKET CENTRIFUGE

MODEL SCPC E

Strengthened by our knowledge and experience in the design and fabrication of centrifuges, and as a result of the various industries that we serve, we have been able to adapt our centrifuges to a wide range of manufacturing sectors such as the chemical / pharmaceutical, textile, and machine-tooling industries to create innovative and unique solutions that address the specific requirements of the food industry.

|

|

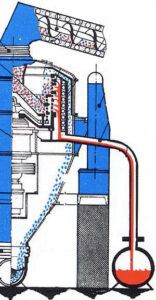

| Continuous centrifuge line Model SCPC E – tallow processing |

Applications:

Continuous separation of tallow and flour

- Rendering

- Liquid tallow recovery

- Seafood byproducts after cookingOther applications are possible with different food products (lemon / orange peels…)

Operating Principle:

The two stage basket consists of two radial screens with vertical slots. The lower stage acts as a pusher with adjustable advance and retract, using a hydraulic cylinder. The material to be dried displaces the previously dried material as a function of the pusher stroke. The dried material is transferred to the discharge chute, to be further processed by downstream equipment.

|

ROUSSELET ROBATEL can accommodate various production requirements, and with our extensive expertise, we can provide specially designed machines with ancillary equipment upon request.

Downloads: